A major international pharmaceutical company launched a new drug to the market. The drug was produced in Europe and during the manufacturing process a chiral resolving agent was used to separate the two enantiomers of an intermediate for the final active pharmaceutical ingredient.

The pharmacutical company had developed a laboratory process for the recovery of the resolving agent but they did not have the spare manufacturing capacity to implement it. They contacted Witton Chemical Company to act as their contract manufacturer and drier. We adapted their outline process to initially work in our existing plant.

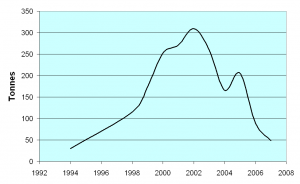

The volume of material grew over the following years peaking at over 300 tons per year of resolving agent recovered.

Continual optimisation and improvement is demonstrated by :-

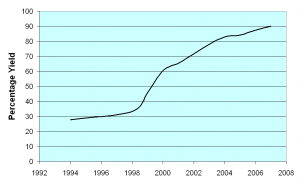

- The yield was increased 3 fold from less than 30% to nearly 90%.yield

- This increase in yield allowed over 200 tons of additional product to be recovered giving a saving in excess of £1 million to the customer.

- Prices were reduced exceeding the customer’s target against raw material price inflation outside of our control

- Approximately 20,000 tonnes of liquors were reprocessed to yield nearly 2000 tonnes of resolving agent.

- Production capacity was increased by a factor of 4, ahead of demand with no shortfalls in supply.

- On Time Delivery 100%

- First-Time Quality 99.98% (Representing just one batch in 4500 being identified as out of specification)

The recovery business also required:-

- The management of trans-frontier waste shipments

- The staged installation of new plant and equipment to allow capacity to grow with demand

- Process modifications to maximise the yield and through-put as the varying combination of different reactors, centrifuges and driers were installed and used.

- HSE and Quality audits.

Once the drug was off patent sales declined and their European production ceased as did our recovery operation. However, this customer later approached us to manufacture a different material required by a different European site manufacturing a different drug.