+44 (0) 1638 716001

Acriflow Dispersing Agents from Witton Chemical

A series of polyacrylic acids and their salts with a range of molecular weights supplied as aqueous solutions. They are used as dispersing agents in a wide number of industrial applications to eliminate deposits or reduce the viscosity of slurries.

Acriflow Properties

| Acriflow UL2 | Acriflow 041-S | Acriflow 141-S | Acriflow 641-S | |

|---|---|---|---|---|

| Viscosity (cps) | 70 – 120 | 100 – 400 | 300 – 650 | 3000 – 7000 |

| Molecular Weight | 1500 – 2500 | 3500 – 5500 | 7000 – 11000 | 30000 – 70000 |

These are typical properties for the standard sodium polyacrylate. Potassium, ammonium or other salts can be provided to special order, as can the un-neutralised acid.

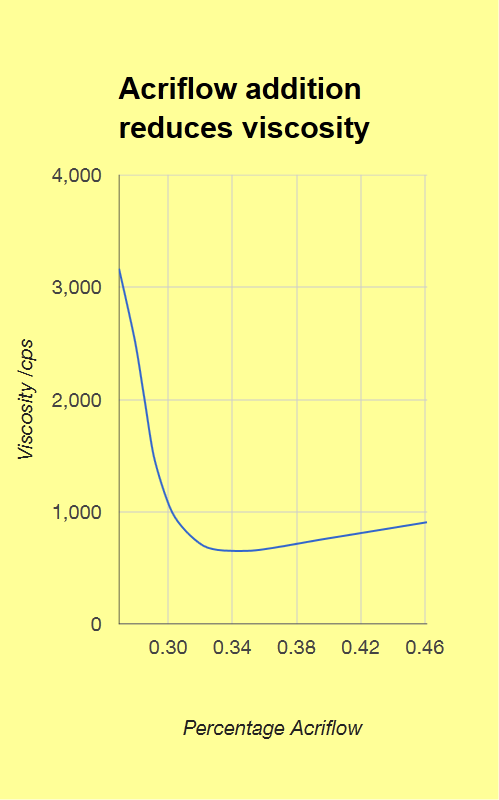

Acriflow products may be used in water-based formulations to increase the solids loading of the required mineral dispersion, or to reduce the working viscosity at a given solids content. This increases process efficiencies and reduces costs. Optimum conditions for each application can be determined by the preparation of viscosity-concentration curves as illustrated below.

In water treatment applications Acriflow assists in the prevention of scale formation, thereby improving operating efficiency and reducing downtime. Other benefits that have been observed include rapid wetting-out, finer dispersion characteristics, higher solids loading, improved stability and lower fuel costs.

Dispersants are used in the following industries:

- Adhesive and latex manufacture

- Paint and coating

- Cement manufacture & Concrete laying

- Paper making

- Pigment dispersion

- Mining and mineral processing

Acriflow Grades

We recommend Acriflow 041S as our workhorse dispersant of choice, but some applications see increased benefit from slightly different polymer chain lengths. To that end we offer a lower (Acriflow UL-2) and higher (Acriflow 141) molecular weight product. For applications requiring a significantly higher molecular weight, we offer Acriflow 641-S. We also offer ammonium salts variants in Acriflow 041-SA and Acriflow 141-SA. If no counter-ion is required, we can supply un-neutralised polyacrylic acid versions of all grades, including Acriflow UL-2 Acid, Acriflow 041-S Acid, Acriflow 141-S Acid and Acriflow 641-S Acid. Other salts can be provided to special order.

To receive a current price for the supply of Acriflow, please complete our quotation request form.

If you need further information, would like a sample, or would like to discuss the supply of a bespoke grade please contact us.